IT'S YOUR RIDE,

JUST BETTER

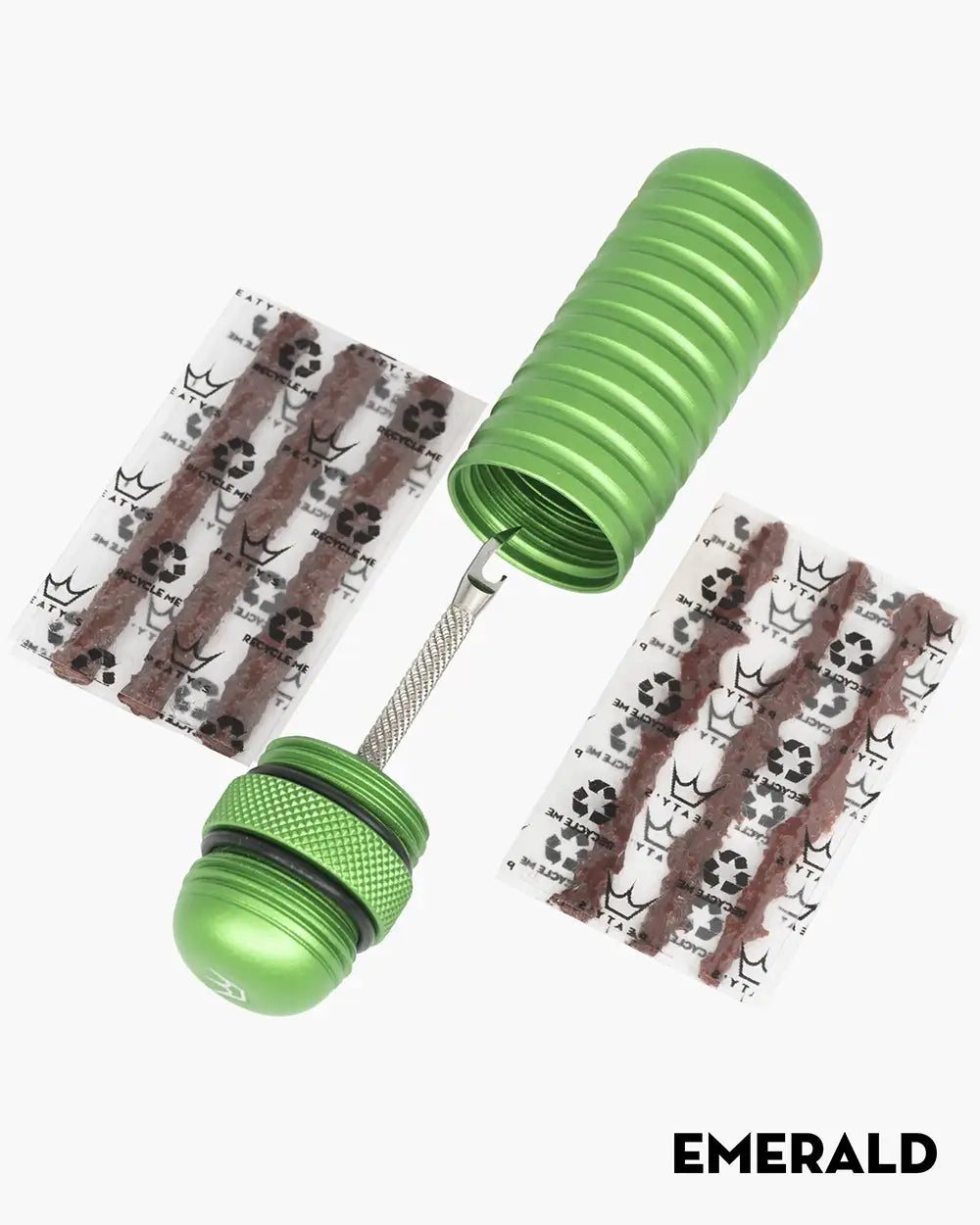

Peaty's Holeshot Tubeless Puncture Plugger Kit

The quickest and easiest way to fix punctures that sealant can't.

Without a tyre plug, a tyre with a snakebite would typically end up with an innertube in it or worse - going in the bin!

Key Product Features

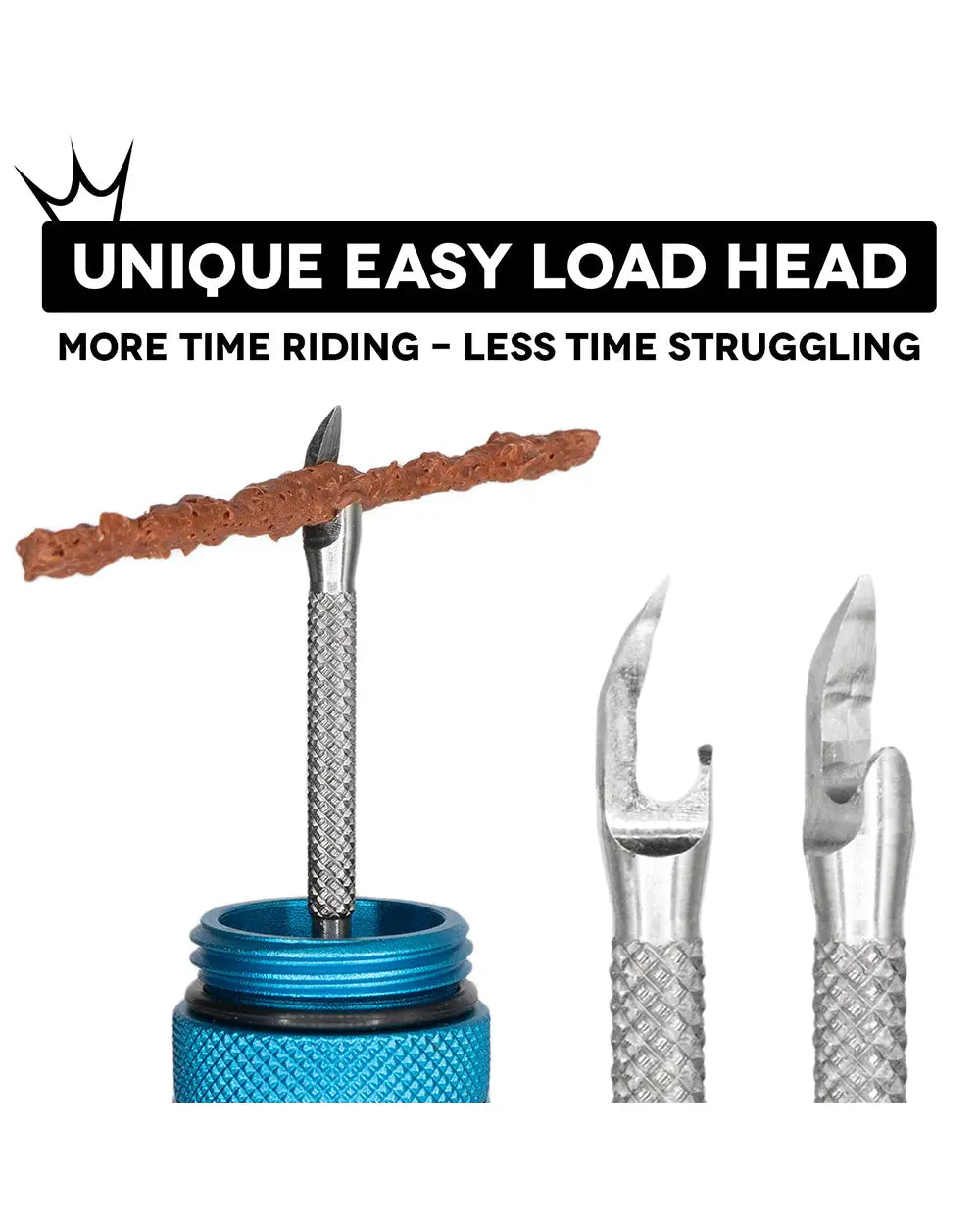

- Unique single-sided fork design.

- Leaves the plug in place each time without pulling it back out of the tyre

- The fork is sharp tipped & as slim as possible so it doesn’t widen the size of the hole already there Like most traditional products on the market

- Knurled body and ribbed lid / handle for extra grip.

- Fork made from 316 stainless steel.

- Body made from anodised 6061 aluminium.

- Weather sealing O-rings make the tool waterproof when assembled

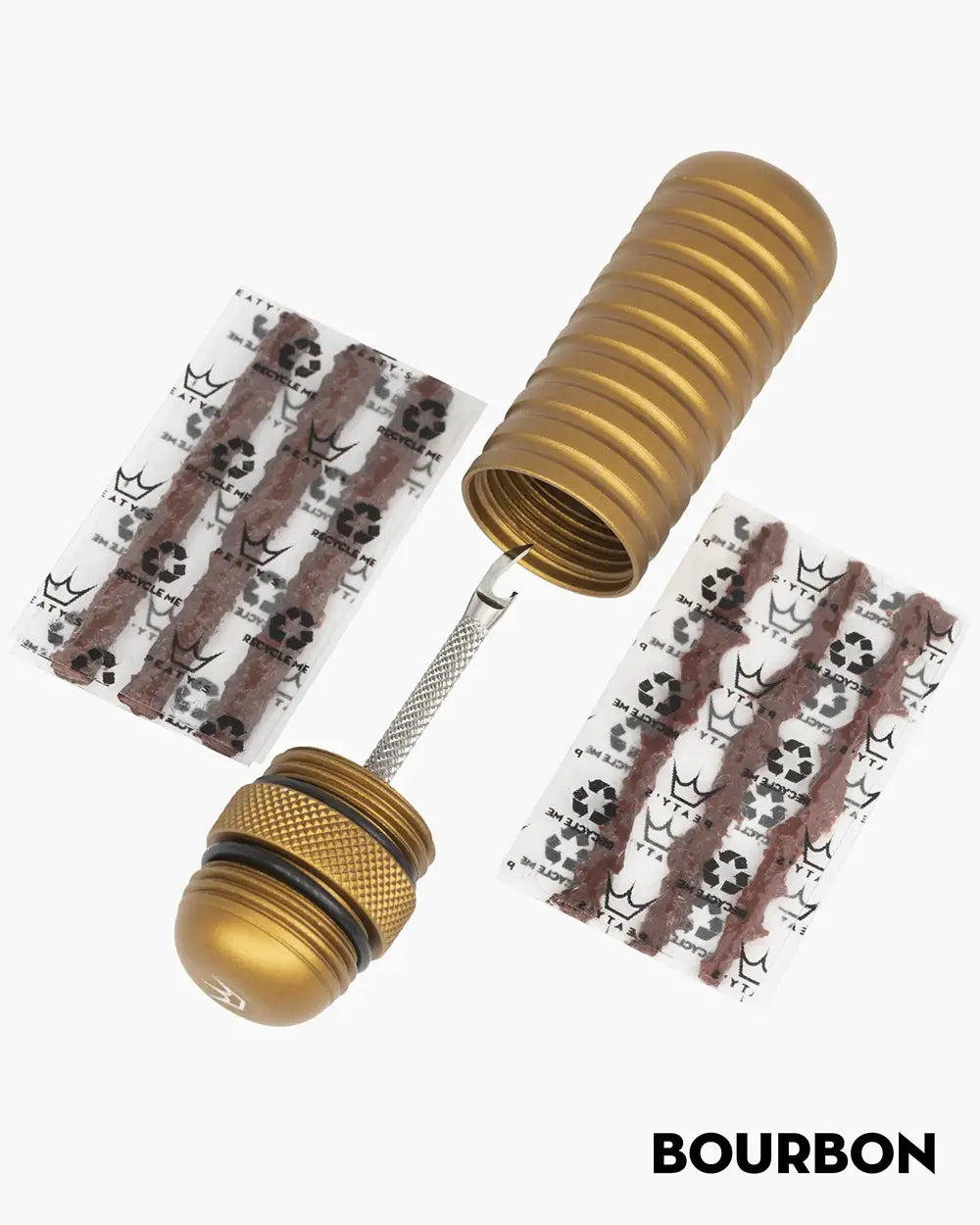

- Available in 12 x Chris King colours

PRODUCT INFORMATION

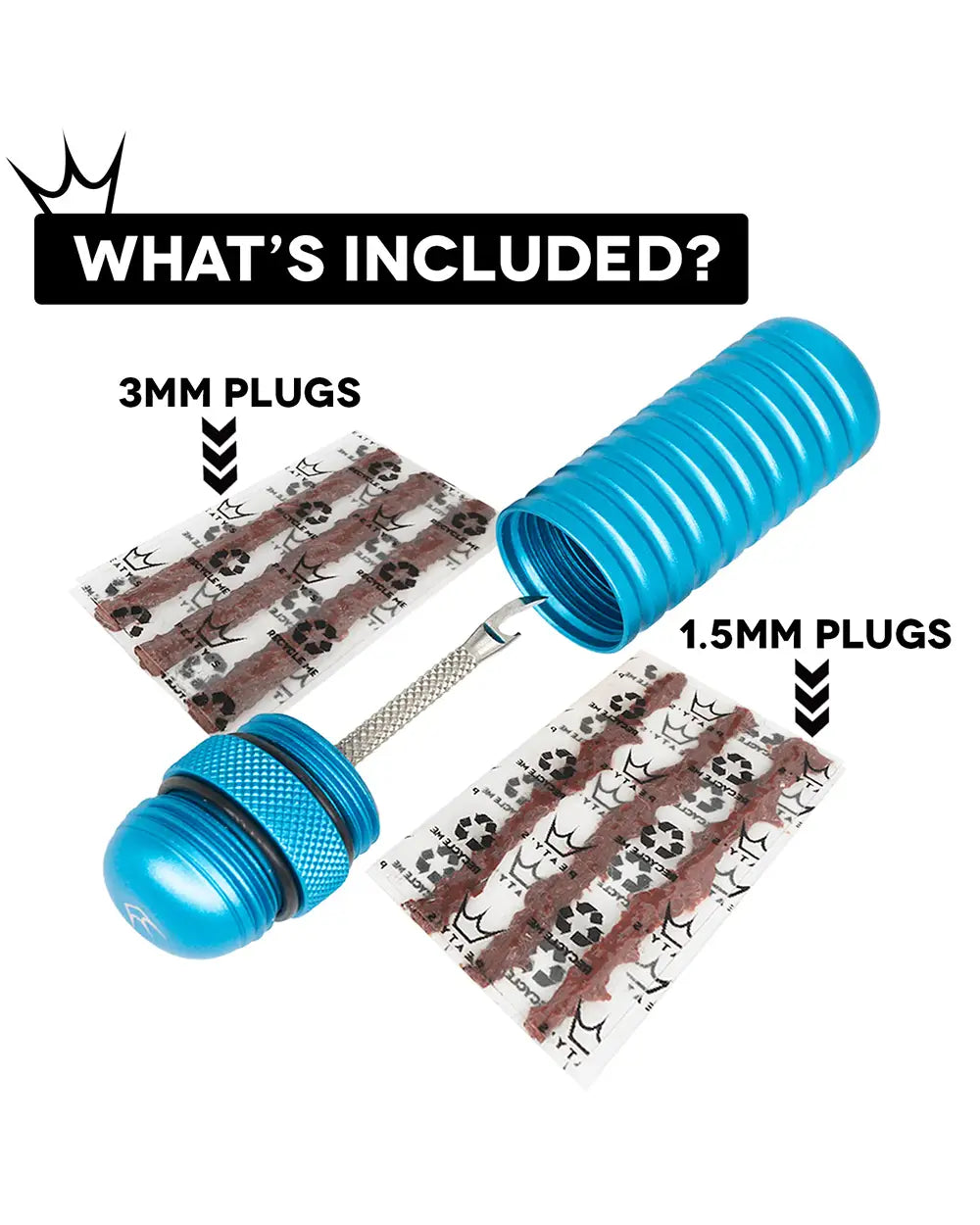

WHAT'S INCLUDED?

Each kit comes with:

- One sheet of 3mm plugs

- One sheet of 1.5mm plugs

These store wrapped around the fork, neatly hidden away inside the tool pod.

SAVE A TYRE - SAVE A RIDE

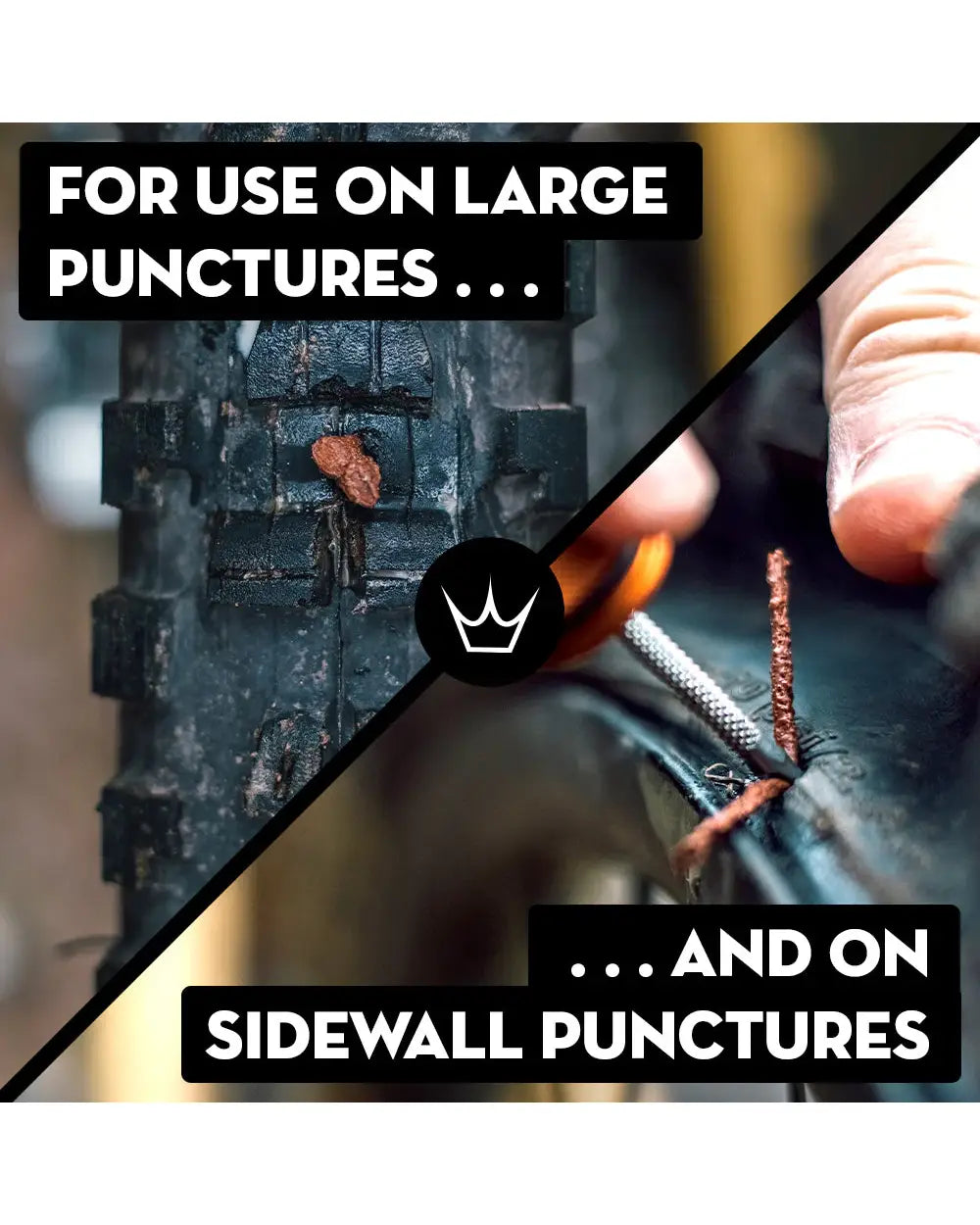

When you ride tubeless, you need to be prepared for every eventuality. There are some holes you just can’t fix with tubeless sealant - the classic is a pinch flat puncture or “snake bite” where the soft tyre is pinched between the edge of the hard rim and a much harder rock. If you’re lucky enough to not crack your rim, you’re very likely to end up with two holes in your tyre, one on top of the tyre and one right next to the tyre bead. Holes down by the tyre bead are the nemesis of tyre sealant since the centrifugal forces created by a spinning wheel fling sealant outwards, to the top of the tyre, leaving no sealant down by the bead. To make things even worse, cornering flexes the tyre bead causing the hole to open up again, so, even if sealant does temprarily fix it, it's likely to be opened back up again with cornering forces. Without a tyre plug then, a tyre with a snakebite would typically end up with an innertube in it or worse - going in the bin!

NOT JUST AN ‘OFF-THE-SHELF' PRODUCT

Tubeless tyre plug tools have existed for years. Most have taken what existed already for motorbikes and just shrunk it for mountain bikes. Here at Peaty's we have redesigned the tubeless tyre plugger to make fixing your tyre as simple and easy as possible.

UNIQUE FORK DESIGN

Peaty's unique single-sided fork design allows for multiple plug sizes to be easily rolled into the dip of the fork and pushed straight into the tyre. The open side to the fork then allows for the tool to be easily pulled back out of the hole, without pulling the plug out with it. No fumbling around with your gloves on trying to thread a needle like you have to with a traditional fork design, this is super quick to apply and delivers perfect results every time.

DESIGNED BY RIDERS, FOR RIDERS

Made from high quality 316 stainless steel, the fork has been designed to be as short as possible to reduce the chance of you puncturing your rim tape when inserting a plug. The fork has also been designed with a reaming texture on the shaft, to clean out punctures before plugging, and to be as slim as possible, so it doesn’t widen the size of the hole already there.

SMALL AND COMPACT

The plug sheets store within the tool itself and the whole thing is designed to be as small and lightweight as possible for easy storage.

EU Authorised Representative Details

INSTRUCTIONS

- Unscrew the lid from the tool, remove the plug sheets and put them somewhere safe.

- Screw the cap onto the base of the fork to create a sturdy handle.

- Find the puncture and remove any debris by cleaning the hole using the spikey knurled texture on the fork shaft.

- Choose the right sized plug to fill the hole, it's always best to go slightly bigger than the hole - too small and it’ll pull back out again.

- Roll the middle of the plug tightly into the dip of the fork.

- Pinch the tyre tightly to isolate the puncture then - taking care not to push too far in and pierce the rim tape - push the plug into the hole, leaving about 10mm sticking out.

- Pull out the fork, making sure you leave the plug inside the tyre.

- Wrap the plug sheets back around the fork and screw the lid back on.

- Re-inflate to the right pressure with your Holeshot CO2 Tyre Inflator.

- Ride!

CAUTION

WARNING: Keep out of reach of children. This tool is sharp, please use with care.

DELIVERIES AND RETURNS

Please choose your location from the dropdown below:

United States

France

Germany

Netherlands

Austria

Belgium

Czech Republic

Denmark

Finland

Hungary

Ireland

Italy

Poland

Portugal

Spain

Sweden

Our dedicated warehouse team is committed to processing and shipping your orders as swiftly as possible. Thank you for your patience during peak periods such as Christmas, Thanksgiving, Black Friday, and promotional sales. Should there be any significant delays, we will make sure to keep you informed.

If you have any questions about your order, please feel free to contact us. We’re here to help!

For the UK and for countries outside of US and EU, please use peatys.co.uk.

US & EUROPEAN CUSTOMS AND DUTY FEES

All orders are shipped from either inside the US or inside the EU so are NOT subject to international or UK to EU customs and duty fees.

RETURNS

If you are unhappy with your purchase, you have 30 days to return your items to us.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging. Please ensure they are packaged appropriately to avoid damage during transit.

Please note, customers are accountable for return shipping charges. We suggest using a recorded or signed for delivery service to ensure the parcel is tracked and insured. All parcels are the customer’s responsibility until we receive them.

For further information, please visit our Refund Policy page.

FURTHER QUESTIONS?

Check out our FAQs for answers to common questions, or contact us for more.

FAQS

How far should I insert the tubeless tyre plug?

We recommend inserting tyre plugs so that, when the fork tool is removed, there is around 10mm of excess plug left on the outside of the tyre. This will create a ‘bulb’ behind the puncture to hold the plug more securely when the tyre is pumped back up. It will also prevent the plug from being pushed inside the tyre while riding.

What’s The Best Way To Remove A Tubeless Plug From The Plug Sheet?

With our unique single-sided fork design you don’t really need to touch the plugs at all. Simply spread apart the plug sheets and - using the plugger tool like a fish hook - hook the plug straight out of the sheet! Doing it this way means you’ve less chance of ruining the sticky surface of the plug by touching it with your filthy fingers or gloves.

How Do Tubeless Tyre Plugs Work?

Our tyre plugs are made from an extremely sticky butyl rubber compound. When inserted into a clean, dry tyre, these butyl plugs will stick to the rubber tyre and, providing the puncture is not too large, can create an airtight seal by themselves. On larger punctures you may see some Tubeless Sealant still escaping while the sealant then seals any remaining gaps. If inserted into a puncture which is surrounded by Tubeless Sealant then we recommend cleaning the hole as best as possible with the inbuilt reaming texture on the fork shaft to try and create a fresh dry surface for the plugs to bond to.

Can I Use Tubeless Tyre Plugs On Road, Gravel And Cyclocross Tyres With Low Knobbles Or Even Slicks?

In short, yes You may use a tyre plugger on road, gravel and cyclocross tyres - You may just feel some small bumps for the first few meters with slick tyres until the plug ‘tails’ on the outside are flattened down.

Why Aren’t Your Plug Sheets Made From Paper?

We tried for a long time to use paper for our plug sheets but when riding in the rain, or removing plugs with wet fingers, the paper plug sheets can soon disintegrate and cover the sticky plugs with a fine film of paper pulp - rendering the plugs useless. Unusable plugs and an unfixed tyre are a far worse scenario for the planet - and for you out in the middle of the woods - so the greater good here was to use durable recyclable plastic instead.

My Plug Keeps Firing Back Out Of The Hole?

If the plug will not stay in the hole then it could be that the hole is not clean / dry enough when inserting the plug or the puncture is too large for the hole.

Ensure that you use the reaming tool to clean and roughen up the hole before inserting a plug - this will enable the plug to grip your tyre better. If the hole is too large and you’re using 1.5mm plugs then try using a 3mm plug instead. If you’re already using a 3mm plug then you can try putting two plugs into one hole.

How can I load a plug into the tool for instant use when racing?

If you want to preload a 3mm plug for an instant fix, simply skewer it on the prong of the fork. That will keep it in place and the hole will ‘heal’ when it’s pushed into the tyre.

Can I Buy Refills Of The Plugs?

Yes you can get packs of 4x 1.5mm or 4x 3mm refills in the Peaty’s online shop or wherever you bought your plug tool.

Will The Tool Work With Other Plugs?

Yes you can use any other brand of butyl plugs if you need to but we spent extra time making ours work really well so you’ll get the best results using Peaty’s plugs.

Do I Need To Cut The Plug Down?

We pre cut our plugs so that you’ll just have a short tail outside the tyre, which will flatten down smoothly once you start riding. Cutting it down makes it more likely that the plug will come out (or fall into the tyre) later.

SAVE A TYRE, SAVE A RIDE

When you ride tubeless, you need to be prepared for every eventuality. There are some holes you just can’t fix with tubeless sealant.

Without a tyre plug, a tyre with a snakebite would typically end up with an innertube in it or worse - going in the bin!

UNIQUE FORK DESIGN

Peaty's unique single-sided fork design allows for multiple plug sizes to be easily rolled into the dip of the fork and pushed straight into the tyre. This is super quick to apply and delivers perfect results every time.

DESIGNED BY RIDERS, FOR RIDERS

Made from high quality 316 stainless steel, the fork has been designed to reduce the chance of you puncturing your rim tape when inserting a plug. It also has a reaming texture on the shaft, to clean out punctures before plugging, and to be as slim as possible, so it doesn’t widen the size of the hole already there.